|

Hot dipped galvanized line for pipe

Hot-dip galvanizing tube & pipe line

Introduction of the hot-dip galvanizing

Hot-dip galvanizing is a form of galvanization. It is the process of coating iron or steel with a thin zinc layer, by passing the steel through a molten bath of zinc at a temperature of around 860 ¡ãF (460 ¡ãC). When exposed to the atmosphere, pure zinc reacts with oxygen to form zinc oxide, which further reacts with carbon dioxide to form zinc carbonate, a dull grey, fairly strong material that stops further corrosion in many circumstances, protecting the steel below from the elements. The process of hot-dip galvanizing results in a metallurgical bond between zinc and steel with a series of distinct iron-zinc alloys. Galvanized Pipes & Tubes has long been one of the most used building materials in the world. For decades, designers, builders & consumers seeking long term structural performance, in the tuff outdoor applications, have turned to zinc coated steel pipes. Galvanized Pipes resist the attack of wild, water & road salts. Galvanized Steel if the one, that's been covered with a layer of zinc metal. During galvanizing, steel is immersed in a molten zinc bath, ensuring a tough, uniform barrier coating. Zinc's natural corrosion resistance provides long-term protection, even in outdoor environments. Apart from preventing water corrosion, it is equally effective in dry & indoor environment.

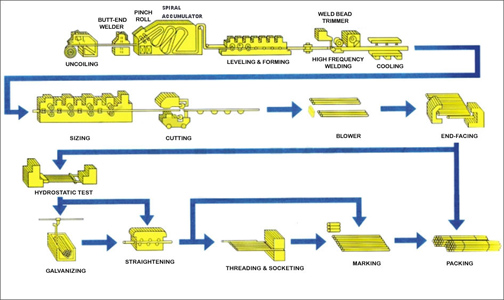

Process chart:

Hot-dip galvanizing tube/s alsopipe

Hot dip galvanized tubes Hot dip galvanized pipes Hot dip galvanizing tubes Hot dip galvanizing pipes

Galvanized steel pipes are covered by a layer of zinc, which are mostly used in structural applications and be available in various sizes and shapes based on the customers' requirements. The hot-dip galvanized steel pipe is formed with high quality welded tube and advanced galvanization technology and equipment, both inside and outside surface are smooth, without black spot or bleb. It features high corrosion resistance and is widely used as wire tubing under the poor condition.

Hot-dip galvanizing tube & pipe line

Introduction of the hot-dip galvanizing

Hot-dip galvanizing is a form of galvanization. It is the process of coating iron or steel with a thin zinc layer, by passing the steel through a molten bath of zinc at a temperature of around 860 ¡ãF (460 ¡ãC). When exposed to the atmosphere, pure zinc reacts with oxygen to form zinc oxide, which further reacts with carbon dioxide to form zinc carbonate, a dull grey, fairly strong material that stops further corrosion in many circumstances, protecting the steel below from the elements. The process of hot-dip galvanizing results in a metallurgical bond between zinc and steel with a series of distinct iron-zinc alloys. Galvanized Pipes & Tubes has long been one of the most used building materials in the world. For decades, designers, builders & consumers seeking long term structural performance, in the tuff outdoor applications, have turned to zinc coated steel pipes. Galvanized Pipes resist the attack of wild, water & road salts. Galvanized Steel if the one, that's been covered with a layer of zinc metal. During galvanizing, steel is immersed in a molten zinc bath, ensuring a tough, uniform barrier coating. Zinc's natural corrosion resistance provides long-term protection, even in outdoor environments. Apart from preventing water corrosion, it is equally effective in dry & indoor environment.

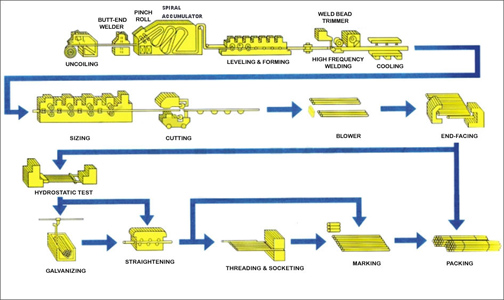

Process chart:

Hot-dip galvanizing tube/s alsopipe

Hot dip galvanized tubes Hot dip galvanized pipes Hot dip galvanizing tubes Hot dip galvanizing pipes

Galvanized steel pipes are covered by a layer of zinc, which are mostly used in structural applications and be available in various sizes and shapes based on the customers' requirements. The hot-dip galvanized steel pipe is formed with high quality welded tube and advanced galvanization technology and equipment, both inside and outside surface are smooth, without black spot or bleb. It features high corrosion resistance and is widely used as wire tubing under the poor condition.