|

ZG165 high frequency welded pipe mill line

Layout flow:

Strip material → decoiler → shear and welder → accumulator → forming and sizing machine → flying saw → packing

Moreover, include: electric control system, high frequency welder.

Line composition:

V-shape pre-discharging table (V coil stand)

Hydraulic charging wagon (coil car)

Hydraulic discharging machine (uncoiler)

Hydraulicshear and TIG welder.

Horizontal strip accumulator.

Forming, welding, cooling and sizing section. drive motor: DC 132 kw+ 132 kw

Computer flying saw cut-off.

Straightener

End milling and chamfering machine

Baling press

Driven roller run out table, Inspection table & collectors.

Solid state H.F. induction welder: 400 kw, solid state type

Rolls: rolls are manufactured out of AISI D3 D2 or E52100

Hydraulic units

Electrical panels

Specifications:

Material to be processed: carbon steel, cold hot rolled pre slit strip coils of weld able grade with max. 0.2% carbon

Type of production: round tubes, squar, square and rectangular hollow sections

Round tube outside diameter: min 50.8, max 165mm

Square hollow section: min 40x 40, max 130 x 130 mm

Rectangular hollow section: min 40 x 60, max 100x 160 mm

Tube thickness: min 1.8 max 6.0 mm

Forming line speed: max 55 m/min

(Square and rectangular hollow shapes are produced at lower speeds depending on side to wall thickness ratio)

Tube cut length: min 4 max 15meter

Length accuracy: ± 3mm

High frequency welded pipe production line

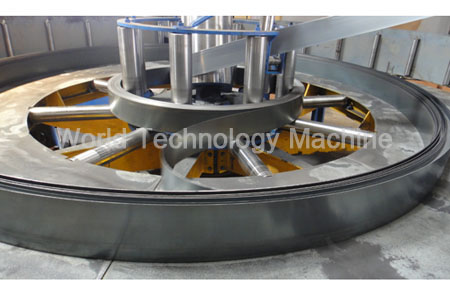

Roller

Decoiler

Accumulator

Layout flow:

Strip material → decoiler → shear and welder → accumulator → forming and sizing machine → flying saw → packing

Moreover, include: electric control system, high frequency welder.

Line composition:

V-shape pre-discharging table (V coil stand)

Hydraulic charging wagon (coil car)

Hydraulic discharging machine (uncoiler)

Hydraulicshear and TIG welder.

Horizontal strip accumulator.

Forming, welding, cooling and sizing section. drive motor: DC 132 kw+ 132 kw

Computer flying saw cut-off.

Straightener

End milling and chamfering machine

Baling press

Driven roller run out table, Inspection table & collectors.

Solid state H.F. induction welder: 400 kw, solid state type

Rolls: rolls are manufactured out of AISI D3 D2 or E52100

Hydraulic units

Electrical panels

Specifications:

Material to be processed: carbon steel, cold hot rolled pre slit strip coils of weld able grade with max. 0.2% carbon

Type of production: round tubes, squar, square and rectangular hollow sections

Round tube outside diameter: min 50.8, max 165mm

Square hollow section: min 40x 40, max 130 x 130 mm

Rectangular hollow section: min 40 x 60, max 100x 160 mm

Tube thickness: min 1.8 max 6.0 mm

Forming line speed: max 55 m/min

(Square and rectangular hollow shapes are produced at lower speeds depending on side to wall thickness ratio)

Tube cut length: min 4 max 15meter

Length accuracy: ± 3mm